Traditionally, the close proximity of assembly workers would put them at high risk of exposure to an airborne virus. This has been a huge help throughout the coronavirus pandemic. The number of tasks robots can execute has also grown.

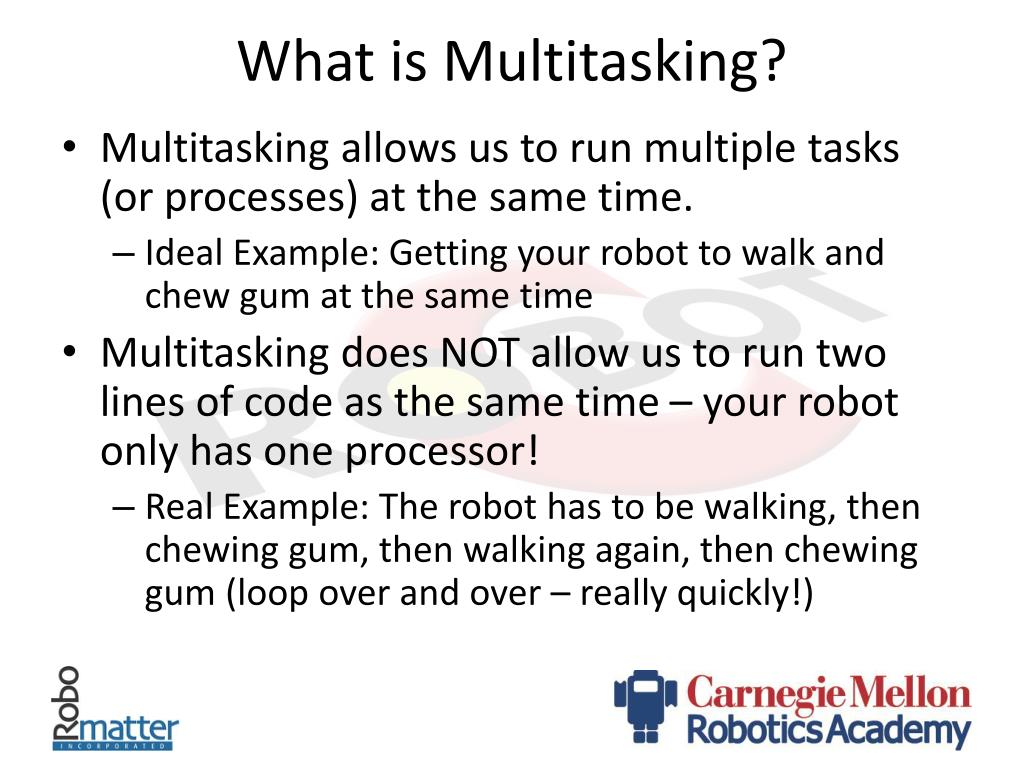

ROBOTC MULTITASKING OFFLINE

Robot programs created using these simulators are called offline programs, and these programs can be directly copied to the physical robots and executed.

There are 3D simulators which can simulate the robot’s work cell with a high degree of accuracy.

ROBOTC MULTITASKING CODE

These programs are created using internal or external code editors or even using recordings of the robot's actions. Each program is an aggregation of a series of commands that the programmer packages before uploading. These controllers - hardware boxes with embedded computers that run the programs necessary for a specific task - often contain multiple programs which programmers can upload from virtually anywhere. You see, robots have controllers that run their programs.

Once installed, robots can be reprogrammed remotely to execute new movements according to the manufacturer's specifications.

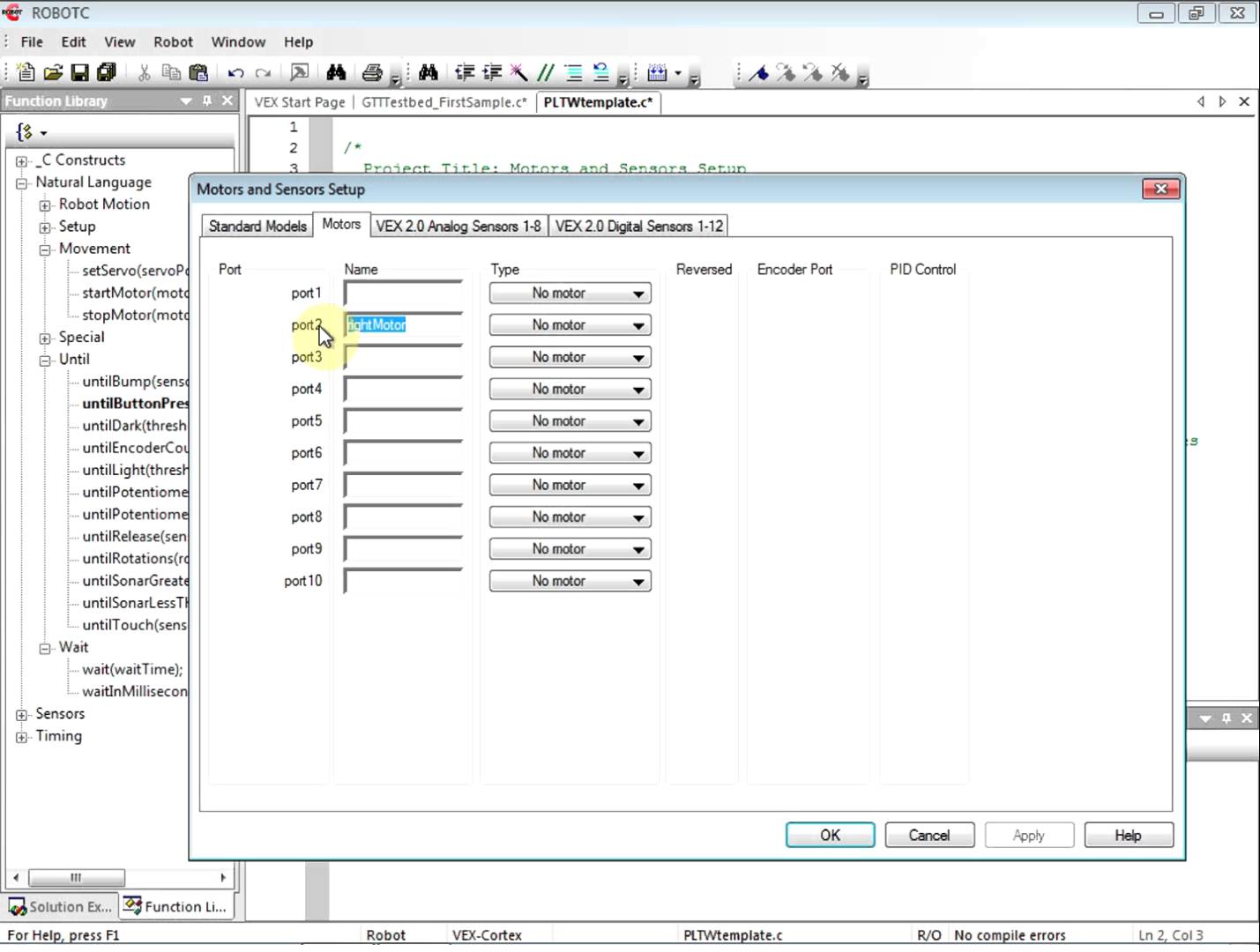

ROBOTC MULTITASKING SOFTWARE

A factory can outfit its existing robots with a system of low-cost software components to implement multi-tasking. Offline robot programming: Efficient and cost-effectiveĪ company might hesitate to make their robots programmable, thinking the endeavor involves huge costs and brand-new hardware, but no new hardware is necessary. This adaptability makes multi-tasking robots very useful in the domain of high-mix, low-volume manufacturing. Today, manufacturers can start the day with a floor of robots performing one task, then finish the workday with those same robots performing a different set of tasks. They can reduce production cycles and optimize asset utilization. Modern industrial robots are more connected, intelligent, and versatile than their predecessors. All that costly, time-consuming maintenance is being wiped away, saving labor, resources, and money. Although machine-to-machine communication is not yet mainstream in manufacturing, it’s on its way. In some of the more modern plants, machines are communicating with each other, even sending data to remote locations.

Automation is becoming increasingly, well, automated. We live in an age known as the Fourth Industrial Revolution, or Industry 4.0, characterized by smart, adaptable technology. Multiply all this by number of robots on the factory floor, and the potential costs for robots in manufacturing becomes staggering.īut it doesn’t have to be. It also requires technical skills which are not readily available on the factory floor, meaning businesses may have to hire more specialized employees or pay for trainings. This repurposing costs time, labor, and money. If a business ever needed a robot to perform a different task from the one it was programmed to do, it meant taking the robot offline, physically interfacing with the robot, uploading new programming, and booting it back up. For decades, robots were designed and programmed to perform one task and one task only.

0 kommentar(er)

0 kommentar(er)